The use of heavy machinery in pipeline construction has become more and more widespread. In recent years, with the increasing demand for national energy, especially natural gas and oil, the demand for pipeline construction has increased, which has promoted the vigorous development of pipeline construction.

If you’re in this industry, it’s important that your business keeps up with new technology and innovation in heavy machinery for pipeline construction. This is important to guarantee the quality and progress of pipeline project construction. Here’s what you need to know.

Choosing The Right Heavy Machinery for Your Pipeline Construction Project

Different types of pipeline construction machines are suitable for different projects. When choosing a machine, you should first consider the specific conditions of the project site, such as

- The soil type

- Groundwater level

- Pipeline route

Then select the most suitable machine according to the specific conditions.

There are other factors to consider as well when choosing the right heavy machinery for the job. Although you may already have access to certain pipeline equipment, equipment managers must determine whether they have all the necessary heavy machinery to complete the pipeline project from start to finish.

A full sized pipeline project tends to require construction teams to have all the equipment for clearing, stringing, bending, welding, lowering-in, backfill, and cleanup.

Most reputable suppliers will have equipment inventory for each step of the project.

Choosing A Heavy Machinery Manufacturer

There are many manufacturers of pipeline equipment. When choosing heavy machinery, you should not only consider the performance and price of the machine, but also the reputation of the Manufacturer designing and fabricating the equipment.

Additionally, for pipeline-specific projects, it’s a good idea to rent or purchase equipment from a manufacturer that specializes in the production of pipeline-specific machinery.

For example, SUPERIOR Manufacturing has been designing and fabricating specialized pipeline equipment for over 30 years. With extensive history in the pipeline industry, it’s no surprise that SUPERIOR also currently manufacture’s one the broadest range of pipeline specialty equipment in the industry.

Although the manufacturer matters, typically contractors are purchasing or renting their equipment from the supplier versus directly from manufacturers. The best heavy machinery suppliers will only carry high-end brands that have a reputation for maximum productivity and reliability.

Purchasing and renting machinery from reputable suppliers also means that you should have constant access to a responsive support team. 1:1 contact with your supplier ensures that any questions you may have about the equipment will be answered by knowledgeable specialists.

On top of that, it’s important to consider your suppliers’ locations. In general, the best heavy machinery suppliers should have at least one branch location within a 200-200 mile radius around any jobsite they supply equipment to. This ensures field or even shop mechanics are ready to service equipment if necessary.

Regardless of whether you’re renting or purchasing, choosing the right heavy machinery matters. Only by choosing equipment from a reliable manufacturer or supplier can you ensure that the equipment and service will be satisfactory.

Select The Newest, Low Hour Models

Technology is always improving, and new models of pipeline construction machines are always developing. Plus, heavy machinery suppliers inevitably strengthen their own value by investing in top quality equipment, so inventory should always consist of late model, low hour, and high quality machinery. When choosing a machine, you should try to choose the newest model.

Although some project budgets may not oblige, doing so yields less risk as newer equipment will increase productivity and optimize efficiency. It is also more energy-efficient and better for the environment.

Ultimately, your supplier should always be able to discuss inventory options and provide you with all the information you need to ensure you get the best equipment for the job possible.

Consider Customization

Some manufacturers offer customization services. If you have specific requirements for your project, you can consider customization. This will give you a machine that is better suited to your needs and can improve the efficiency of your project.

Project Size Matters

Project size and budget are clearly the most important factors to consider when choosing heavy machinery for your next pipeline construction project.

Depending on the project at hand, equipment managers will need to make decisions regarding the weight and lifting power of the equipment.

Of course, budget is also an important factor to consider when choosing a machine. There are many models and sizes of pipeline equipment on the market, all with different price ranges. For example, larger projects will inevitably require more powerful equipment which often leads to a greater expense.

Make sure to not only compare the price but also the features and options. You should choose a machine that has the features and options you need and is within your budget.

Features of Heavy Machinery For Pipeline Construction

Pipeline construction machines have many features. Most of them fall into three categories:

- Safety features

- Performance features

- Convenience features

Safety Features

Pipeline construction can be a dangerous job. The machine should have some safety features to protect the operator and other workers. For example, it should have an emergency stop button, a safety cage, etc.

Performance Features

Pipeline equipment should consist of various features which enhance the machine’s performance, efficiency, and overall reliability. Although performance features vary depending on equipment type, model, and manufacturers, most revolve around enhanced operating weight, lifting capacity, control types, bed configurations, etc.

Convenience Features

Heavy machinery should be easy to operate and maintain. It should have a remote control, an automatic lubrication system, and a self-diagnostic system. It should be able to work in all weather conditions and terrain.

GPS Tracking

One of the most important features of pipeline construction machines is GPS tracking. GPS tracking can help you track the machine and monitor its performance. It can also help you find the machine if it breaks down or gets lost.

Remote Control

Another important feature of pipeline construction machines is the remote control. With remote control, you can operate the machine from a distance. This is very convenient and can help you avoid danger.

Automatic Lubrication System

An automatic lubrication system is also a very important feature of pipeline construction machines. It can help to keep the machine well-lubricated and reduce wear and tear.

These are some of the features that you should look for when choosing a machine. You should also consider your own needs and requirements. Only by considering all these factors can you choose the best machine for your project.

Additional Options Available

There are also some additional options that you can choose from when purchasing a pipeline construction machine. For example, vacuum lifts, a pipe welding system, etc.

Vacuum Lifts

Vacuum lifts are designed to make your job site much safer and efficient. These machines allow an operator to do the job of several by eliminating the need for a slinging crew, thus saving you money in redundant labor and making the job site safer.

Pipe Welding System

This is a system that welds pipes together. It is often used in repairing pipelines.

Additional Types of Heavy Machinery

Then there are other types of heavy machinery you’ll need on hand when constructing pipelines. Some additional types of pipeline construction machinery includes:

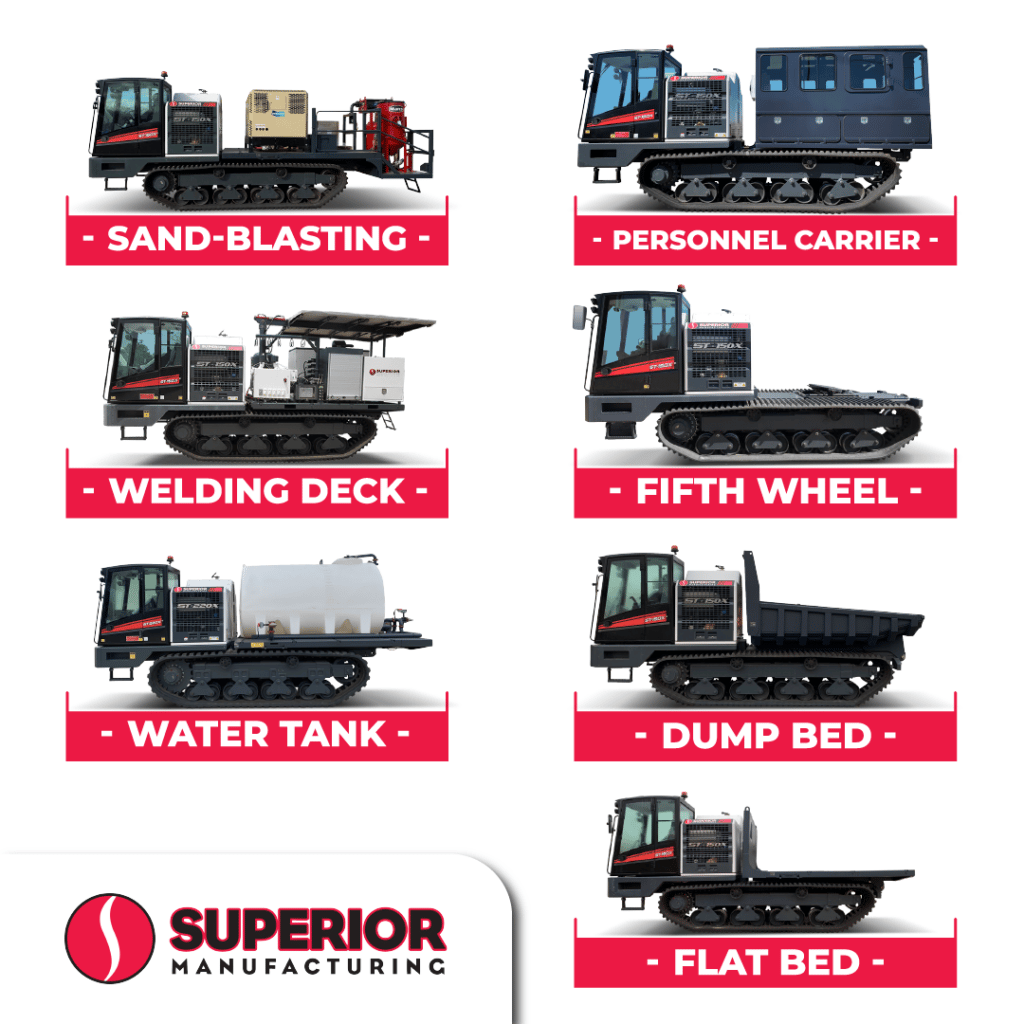

Crawler Carriers

These off-road tractors typically feature military grade rubber tracks. The track system offers high traction and low ground pressure, allowing the carrier to travel on rough terrain while minimizing damage to the environment.

Due to their versatility, Crawler carriers are used in a variety of industries including civil construction, pipeline, mining, and oil and gas. Beyond their ability to overcome rough terrain, crawlers are useful for hauling personnel and a diverse range of heavy objects and debris.

Crawler carriers are known for supporting different attachments and modular bed systems, which make them handy for a multitude of projects. Plus, they tend to be safer than traditional off-road vehicles, as they are less likely to roll over.

High Capacity Excavators

These are excavators that have a higher weight limit than standard excavators. High Capacity excavators are essential for pipeline construction because they can excavate large areas of land with efficiency. They can handle a variety of tasks, including hauling materials, drilling, and operating other heavy machinery.

High-capacity excavators work by using a hydraulic system to lift and move heavy objects. The joysticks inside the cab of the excavator control the hydraulic system.

Some benefits of using a high-capacity excavator include:

- they can lift and move heavy objects that weigh up to 100 tonnes

- they can dig holes, transport materials, and help with demolition

- these excavators are much safer than traditional excavators, as they won’t tip over

Welder Tractors

Welding tractors are most commonly used to fabricate pipeline system joints together.

This heavy machinery is much more efficient than traditional welding methods. They’re able to weld pipes together in a fraction of the time it would take to do it manually. They are versatile and weld a variety of different objects together, including pipes, metal plates, and beams.

Plus they are much safer than traditional welding methods, as they are less likely to cause accidents.

There are many different types of welder tractors, including:

- Pipeline welder tractors

- Plate welder tractors

- Beam welder tractors

- Multi-purpose welder tractors

Pipe Bending Machines

Pipe bending machines do exactly what their name suggests; bend pipes. They are available in many different sizes. There are many different types of pipe-bending machines, including:

- Manual

- Hydraulic

- Electric

- Pneumatic

They are useful to have on hand as they can bend pipes in a fraction of the time it would take to do it manually. They are available in a wide range of sizes, from small machines that can bend pipes up to 50mm in diameter to large machines that can bend pipes up to 1200mm in diameter.

Pipe bending machines can handle many tasks, such as bending pipes for plumbing, electrical, and construction applications.

Padding Machines

These machines are used to add padding to pipes which protects pipes from damage. It is important for pipes to be buried underground, as they are at risk of sustaining damage from rocks and other debris.

Padding machines work by using a hydraulic system to add padding to pipes. Joysticks that are located inside the cab of the machine control the system.

Pipelayers

Pipelayers are a popular type of heavy machinery used to lay, align, and weld underground pipeline systems.

Most models are computerized for automated alignment and welding. Some use lasers to guide the process. Large-scale projects often require multiple pipe layers working together. Pipelayers lay pipe with efficiency, with some models laying up to 1000m of pipe per day.

Most models are computerized for automated alignment and welding which means a better muse of manual labor elsewhere. They can reduce the cost of a project by eliminating the need for manual labor.

Some pipe layers use lasers to guide the pipe-laying process, which results in increased accuracy.

Where to Source Heavy Equipment Machinery

Pipeline machines, pipe bending machines, padding machines, pipe layers, and all the rest are essential pieces of equipment for pipeline construction. They vary in size and function, but all serve the purpose of making pipeline construction projects easier, faster, and more accurate. So where’s the best place to get them?

At W Silver, we make sure to source only the best quality machines from the most reputable brands.

Our team of experts has years of experience in the industry and knows what to look for in a good machine. We also offer competitive pricing to make sure you get the machine you need without breaking the bank.

Whether you’re looking to rent or purchase heavy machinery, we can help you find the perfect one for your needs. We also have the parts and technicians to service and repair your machines, so you can keep them running like new.

W Silver: Your Heavy Machinery Partners

No matter what type of project you’re working on, the right machine can make all the difference. At W Silver, we can help you find the perfect heavy machinery for the job.

Request a quote today and one of our experts will help you find all the machinery you need for your project. We’ll help you to build out the right mix of equipment so your business can handle any construction project requested.